Product Description

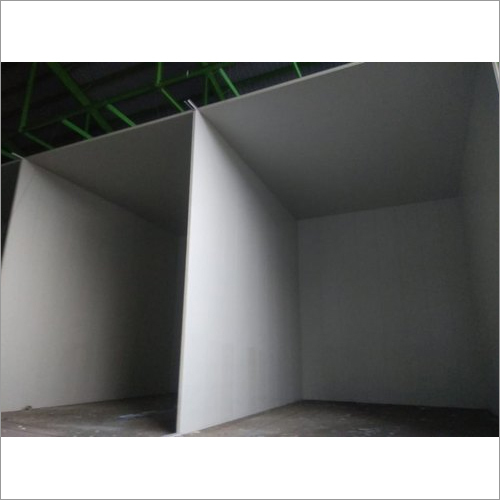

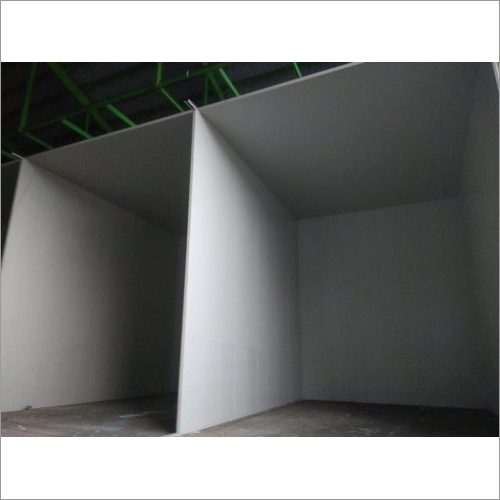

Backed with state-of-the-art infrastructural facilities, we are passionately involved in offering the best quality Clean Room PUF Panel to widely scattered esteemed clients. Ideal for offices, residential, and commercial places, the panel is suitable for making ceiling and cladding application due to its great insulation, high abrasion & corrosion resistance, durability and long shelf life. The surface is well treated with color coating material to guarantee its attractive look and long life. Besides, Clean Room PUF Panel comes in standard shape, and size of 1180mm width.

Optimized Fire and Moisture ResistanceCertified to Class I fire resistance in compliance with IS:12436, these panels are engineered for safety in critical environments. The polyurethane foam core resists moisture penetration, making them reliable for applications where hygiene and protection are paramount.

Precision Modular ConstructionThe tongue and groove edge profiles provide superior joint sealing, resulting in enhanced insulation and reduced contamination risk. Installation is streamlined through modular design, accommodating custom room sizes and allowing for quick assembly during clean room projects.

Versatile Performance and ApplicationPanels feature a range of facings such as PPGI, stainless steel, and aluminum to suit the operational needs of laboratories, operation theatres, or pharmaceutical manufacturing areas. They offer high compressive strength, excellent heat insulation, and strong acoustic properties, fulfilling multiple functional requirements.

FAQs of Clean Room PUF Panel:

Q: How are Clean Room PUF Panels installed, and what makes the process quick and modular?

A: Clean Room PUF Panels utilize a tongue and groove edge profile for precise joint alignment, simplifying modular installation. Panels can be customized to fit specific room sizes and shapes, enabling rapid and seamless construction of clean room environments.

Q: What fire safety standards do these panels comply with?

A: These panels are fire retardant and classified as Class I as per IS:12436 standards, providing enhanced protection in sensitive applications like pharmaceuticals, laboratories, and operation theatres.

Q: Where can Clean Room PUF Panels be used?

A: Clean Room PUF Panels are suitable for a range of settings, including clean rooms, pharmaceutical manufacturing units, laboratories, operation theatres, and healthcare facilities requiring high hygiene, controlled environment, and robust insulation.

Q: What external and internal facing materials are available for these panels?

A: Panels are offered with external facing options including pre-painted galvanized iron (PPGI) or stainless steel, while internal facings can be pre-painted GI, stainless steel, or aluminum to match operational requirements and aesthetics.

Q: How do these panels benefit sound and thermal insulation needs?

A: The rigid PUF core offers excellent acoustic insulation, significantly reducing noise transmission. With a heat transfer coefficient of 0.022-0.024 W/mK, they also provide remarkable thermal insulation, maintaining stable temperatures within controlled environments.

Q: What size and thickness options are available for Clean Room PUF Panels?

A: Standard panel widths are 1180 mm, and thickness options include 40mm, 50mm, 60mm, 80mm, and 100mm. Lengths can be customized up to 6000 mm, with height tailored to the room design, ensuring flexibility for different applications.