Product Description

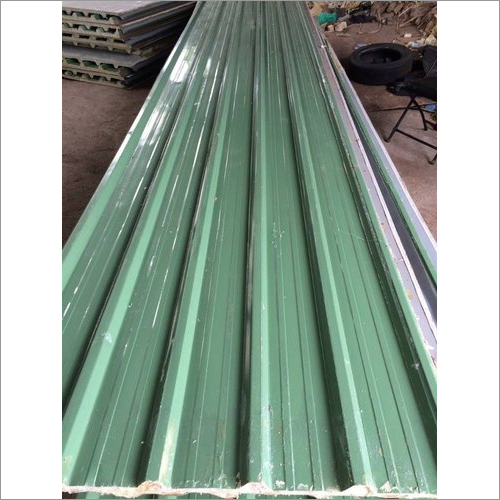

Kakade Sandwich PUF Panel that our well-renowned firm proposes is most extensively utilized in a lot of residential and commercial places for making roofs of outer area having slope 1:15 or more. Made with combination of top-grade PUF, PUR or PIR and Mineralwool Insulation core with approved cold rolled technology, it can be effortlessly fixed by means of top of rib to structure supports. Further, Kakade Sandwich PUF Panel can be conveniently combined with skylights and various other roof opening arrangements.

Product Details:

|

Minimum Order Quantity

|

10 Square Meter

|

|

Model No.

|

KJ1000 RW

|

|

Usage/Application

|

Roofing

|

|

Brand

|

Jindal

|

|

Technique

|

Cold Rolled

|

|

Overall Width

|

1000 mm

|

|

Material

|

PUF

|

|

Country of Origin

|

Made in India

|

|

Weight (Kg/Sq M )

|

9 kg

|

|

U - Value (W/Sq M K)

|

0.6 mm

|

|

Thermal Insulation Minimum Core Thickness

|

25mm

|

|

R- Value (Sq Metres K/W)

|

1.67mm

|

|

Overall Thickness

|

60mm

|

Superior Insulation PerformanceKakade Sandwich PUF Panels offer robust thermal and acoustic insulation thanks to their high 40 kg/m3 PUF core. This feature minimizes energy loss, making them ideal for maintaining consistent cold storage environments and reducing operational costs.

Fire Resistant and Durable DesignEach panel incorporates a fire-resistant polyurethane foam core, coupled with a pre-painted galvanized iron (GI) facing. This combination enhances durability and safety, providing reliable performance in demanding industrial settings.

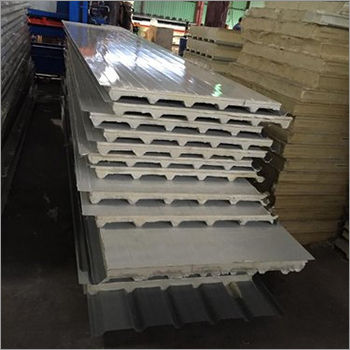

Efficient Panel Joint SystemThe tongue and groove joint ensures a tight, seamless connection between panels. This not only simplifies the installation process but also improves overall insulation efficiency by reducing potential thermal bridging.

FAQ's of Kakade Sandwich PUF Panel:

Q: How does the Kakade Sandwich PUF Panel enhance insulation in cold storage applications?

A: The Kakade Sandwich PUF Panel uses a dense polyurethane foam core (40 kg/m3) to deliver superior thermal and acoustic insulation, ensuring that cold storage areas maintain stable temperatures and quiet environments.

Q: What is the typical process for installing these PUF panels?

A: Installation involves aligning the rectangular panels using the tongue and groove joint, securing them in place, and ensuring proper sealing to maximize insulation and prevent air leaks. Their lightweight and cold-rolled design simplifies handling and installation.

Q: When should you select PUF panels with fire resistance for your project?

A: Fire resistance is crucial when safety and adherence to industrial regulations are required. Kakade Sandwich PUF Panels, with their fire-resistant polyurethane core, are suitable for applications where minimizing fire hazards is a priority, such as in food processing or pharmaceutical facilities.

Q: Where are these panels commonly used in India?

A: These panels are widely utilized across India in cold storage facilities, including commercial refrigeration units, food warehouses, and pharmaceutical storage spaces where strict temperature control is essential.

Q: What are the main benefits of using pre-painted GI facings on PUF panels?

A: Pre-painted GI facing improves the panel's durability, corrosion resistance, and hygiene, making it easier to clean and maintain-important features for industrial and cold storage environments.

Q: How do Kakade's panel joints contribute to improved performance?

A: The tongue and groove joint system provides a secure, airtight seal between panels, enhancing insulation efficiency while also expediting the assembly process.